Separators

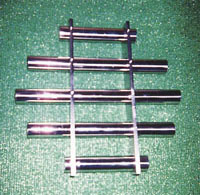

DIA-BAR DB

DIA-BAR DB is a bar magnet containing a rare-earth magnet in a stainless tube. A suitable model is selected based on surface magnetic force and temperature.

mT (tesla) = 10 G (gauss)

| Model | Dimensions | Temperature conditions | Residual magnetic flux density | Surface magnetic force |

| DB1 | φ20×Length |

100℃ or less | 1,250mT |

720〜800mT |

| DB2 | φ23×Length | 200℃ or less | 1,120mt | 900±10%mT |

| DB3 | φ25×Length | 100℃ or less | 1,250mt | 1,000±10%mT |

* If magnetic force exceeding the above is needed, please feel free to contact us. The standard tube material is SUS316L. Titanium tubes are available.

Square DIA-GRID DGS

for simple cleaning

Round DIA-GRID DGH

for simple cleaning

DIA-GRID DGS、DGH

DIA-GRID is a grid magnet consisting of super-high power bar magnets (DIA-BAR) assembled in a grid. DIA-GRID, square or round, can be installed in a hopper or piping. Particles attracted to magnets are removed with air or adhesive tape. Simple cleaning types designed for workability are useful.

| Model | Dimensions | Number of magnets |

| DGS-200 | φ200 | 4 |

| DGS-250 | φ250 | 5 |

| DGS-300 | φ300 | 6 |

| DGH-200 | φ200 | 4 |

| DGH-250 | φ250 | 5 |

| DGH-300 | φ300 | 6 |

A suitable one is selected from three models based on powder fluidity (clogging). We provide magnetic separators having structures designed based on surface magnetic force and the content of metallic foreign particles and on-site workability (simple cleaning), and a series of automatic cleaning separators (DIA-SELF) having electromagnetic functions.

| Model | Simple cleaning | Automatic cleaning | Installation of magnets | Fluidity | Clogging |

| DCH | ○ | ○ | Horizontal | Good | Minor |

| DCS | ○ | ○ | Inclined | Poor | Medium |

| DCV | ○ | × | Vertical | Very poor | Major |

We have developed a DIA-ROTOR series consisting of bar magnets around a rotor to remove iron particles by rotating magnets and a DIA-CANON series to remove iron particles inside piping -- pneumatic piping, spontaneous dropping, etc.

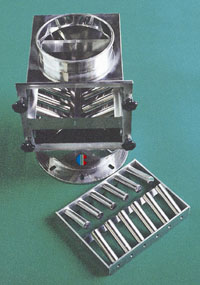

Standard DCH

Simple cleaning DCH

InclinedDCS

VerticalDCV

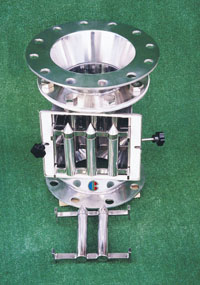

DIA-KONNER DCH、DCS、DCV

DIA-KONNER is a magnetic separator usually used to remove iron particles from powder and granular materials.

It is an iron particle remover with super-high-power magnets (DIA-BAR) assembled in a grid (DIA-GRID) in a case. Select a suitable one from three models.

| Model | Diameter φ(mm) |

Height,H (mm) |

Width,B (mm) |

Number | Throughput (m3/h) |

| DCH-100 | 100 | 250 | 150 | 2+3 | 3 |

| DCH-150 | 150 | 250 | 200 | 3+4 | 6 |

| DCH-200 | 200 | 300 | 250 | 4+5 | 9 |

| DCH-250 | 250 | 350 | 300 | 5+6 | 13 |

| DCH-300 | 300 | 350 | 350 | 6+7 | 18 |

| DCH-350 | 350 | 350 | 400 | 7+8 | 23 |

| DCH-400 | 400 | 350 | 450 | 8+9 | 29 |

| DCS-100 | 100 | 300 | 200 | 4+6 | 3 |

| DCS-150 | 150 | 350 | 200 | 6+8 | 6 |

| DCS-200 | 200 | 400 | 250 | 8+10 | 9 |

| DCV-100 | 100 | 300 | 150 | 7 | 4 |

| DCV-150 | 150 | 350 | 200 | 10 | 8 |

| DCV-200 | 200 | 400 | 250 | 14 | 13 |

| DCV-250 | 250 | 450 | 300 | 15 | 20 |

Manual drawing DAS

Running online

Manual drawing DAS

Cleaning

DIA-SELF DAS(AMS)

DIA-SELF is a simple cleaning separator more advanced than the above simple cleaning separator, DIA-KONNER. It can be cleaned on the spot without removing grid magnets from the case. The magnet is manually drawn out from the line. An automatic model combined with an air cylinder is also available.

* Use of air movement system (AMS)

Conventional separators have all magnets drawn out simultaneously from an external tube with the air cylinder. If magnets are locked in the tube due to some problem, it takes one day to restore separator function. The AMS enables magnets to be removed individually in an external tube with air, keeping external tube surface from being worn and, in case of unexpected accidents, its function is restored by replacing the defective magnets alone, which can be done in hours instead of days.

DIA-ROTOR DRP

The DIA-ROTOR is suitable for powders having relatively high viscosity and poor fluidity. A number of super-high-power magnets (DIA-BAR) is arranged around the rotor, rotated by the motor at a speed suitable for powder dropping, so powders contact the DIA-BAR as efficiently as possible. Rotors of models having apertures 400 square or more have a function similar to that of the DIA-SELF of manual drawing type because rotors are heavy. Models can be cleaned on the spot without removing internal rotors, so that they can be applied to large-aperture lines.

| Model | Aperture (mm) |

Cleaning | Throughput (m3/h) |

|

| By removing rotor | By drawing out rotor | |||

| DRP-200 | 200 square | ○ | △ | |

| DRP-250 | 250 square | ○ | △ | 7 |

| DRP-300 | 300 square | ○ | ○ | 15 |

| DRP-400 | 400 square | × | ○ | 25 |

| DRP-500 | 500 square | × | ○ | 40 |

DIA-CANON DKP

DIA-CANON is suitable for relatively large-capacity, large-aperture lines. A higher-power magnet “cannonball” is provided in a case. Since its throughput is high, it is suitable for rough removal upstream rather than removal of fine iron particles.

It is used also for removing fine iron particles in pneumatic powder piping.

| Model | Aperture |

| DKP-80 | 80A |

| DKP-90 | 90A |

| DKP-100 | 100A |

| DKP-150 | 150A |

The DIA-SLUR Series is used to remove iron particle combined with super-high-power bar magnets (DIA-BAR) and used in the piping of liquid and viscous material manufacturing lines.

Select a suitable one from four models based on liquid fluidity (flow velocity and viscosity). The series includes separators designed both for surface magnetic force and for metallic content and on-site workability. Automatic cleaning separators have electromagnetic functions.

| Model | Liquid fluidity and viscosity | Use | Simple cleaning | Manual drawing simple cleaning | Automatic cleaning |

| DSY | Low | City water, condensates, etc. | × | × | × |

| DSI | ↓ | Before filler | × | × | × |

| DST | ↓ | Paints, drinks, etc. | ○ | ○ | ○ |

| DSH | High | Drinks, retort foods, etc. | ○ | ○ | ○ |

DIA-SLUR DSY

A super-high power magnet is installed in a Y-shaped strainer to ensure iron particle removing. Strainers complete with magnets are fabricated or your Y-shaped strainers currently in use can be provided with magnets by modifying their caps.

| Model | Aperture | Length (mm) |

Magnet diameter (mm) |

Number of magnets |

| DSY-25 | 25A | 115 | 20 | 1 |

| DSY-32 | 32A | 135 | 25 | 1 |

| DSY-40 | 40A | 150 | 25 | 1 |

| DSY-50 | 50A | 180 | 25 | 1 |

DIA-SLUR DSI

These separators are suitable for lines through which the flow rate is low or low-viscosity liquids flow intermittently. They were developed for installation upstream from fillers, but are also used on other lines.

| Model | Diameter | Magnet length(mm) |

| DSI-25 | 1S | 200〜500 |

| DSI-40 | 1・1/2S | 200〜500 |

| DSI-50 | 2S | 200〜500 |

DIA-SLUR DST

These separators are suitable for liquids having medium viscosity other than edible liquids. We have manufactured this type of separator with internal partitions for removal of iron particles from value-added liquids at low flow to keep liquids in contact with magnets as long as possible.

| Model | Diameter | Number of magnets |

| DST-25 | 1S | 3 |

| DST-40 | 1・1/2S | 5 |

| DST-50 | 2S | 5 |

| DST-60 | 2・1/2S | 7 |

DIA-SLUR DSH

These separators are applicable to a wide range of liquids from low-viscosity such as drinks to high-viscosity such as retort food. Their cases are designed so that the product is not collected on the bottom but flows smoothly for food sanitation.

| Model | Diameter | Number of magnets |

| DSH-40 | 1・1/2S | 5 |

| DSH-50 | 2S | 5 |

| DSH-60 | 2・1/2S | 5 or 7 |

| DSH-70 | 3S | 7 |

| DSH-80 | 3・1/2S | 7 |

| DSH-100 | 4S | 7 |